If you’ve ever wanted to refine your chocolate palate, learn the secrets of fine chocolate, or even start your own bean-to-bar brand, there’s no better way than becoming a certified Chocolate Taster. And if you missed the 5th International IICCT Chocolate Tasters Certification Course hosted Cocoashala in Chennai for participants from across the world, you missed one of the most transformative chocolate experiences in India!

For the fifth time, Cocoashala brought this prestigious certification program to India, proving why it remains the most sought-after chocolate course for bean-to-bar chocolate makers, chocolatiers, traditional Indian sweet makers, chocolate entrepreneurs, and fine food connoisseurs. More than just a course, this was an immersive sensory journey, taking participants deep into the world of chocolate tasting and appreciation.

The Art of Being a Chocolate Taster

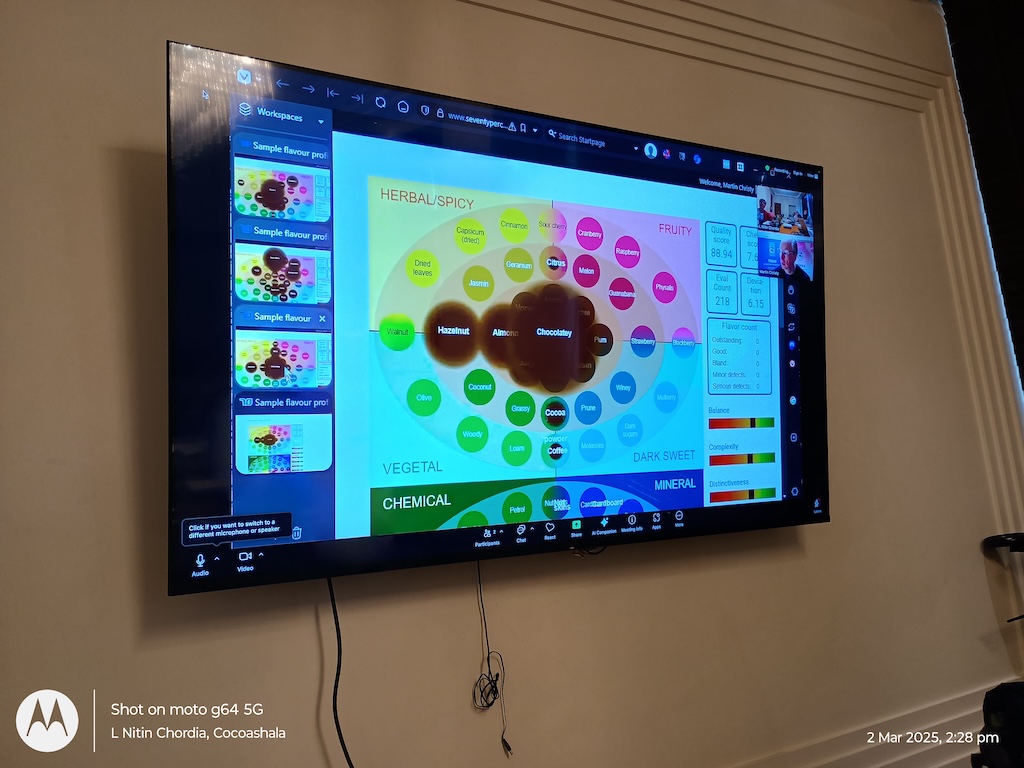

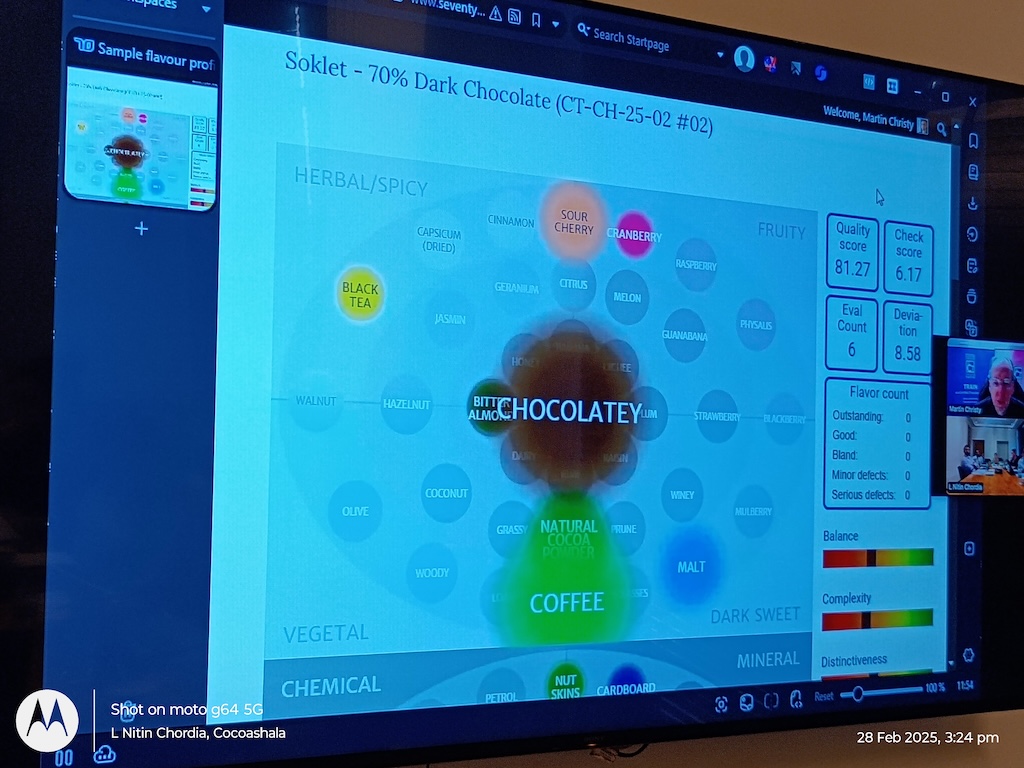

Over 11 immersive days and 3 different states, participants from across India and beyond mastered the art and science of chocolate tasting. They learned how to:

- Identify fine flavor cacao and analyze flavor development

- Detect defects and distinguish between mass-market and premium chocolate

- Appreciate the nuances of various foods and create flavor archetypes

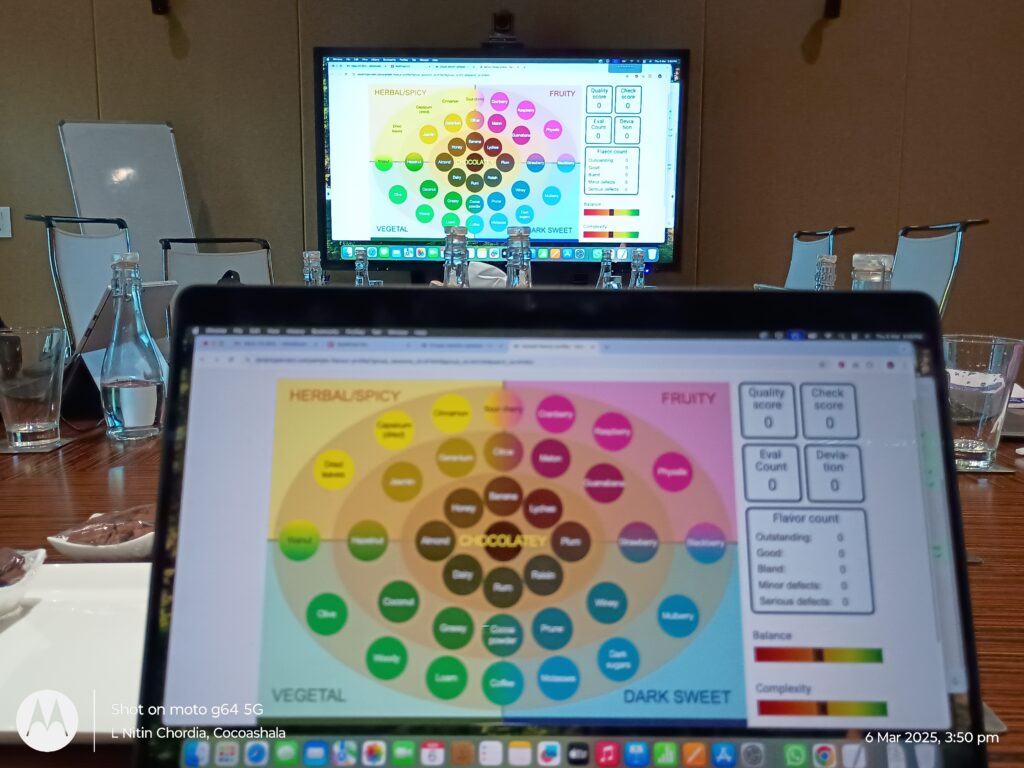

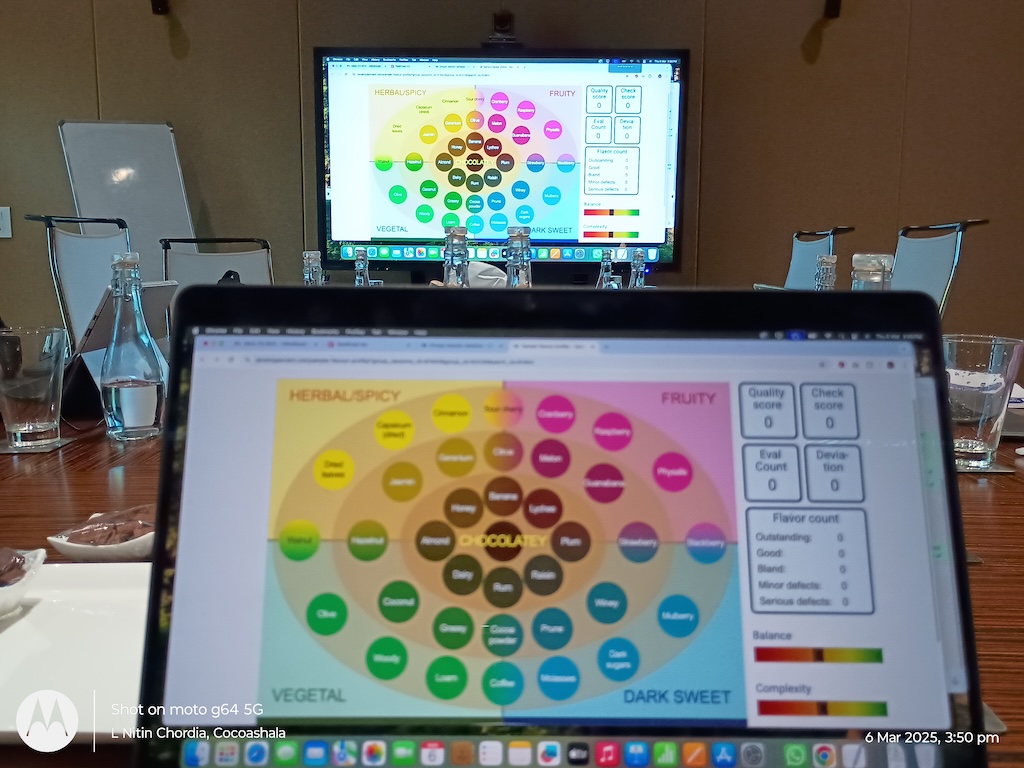

And for the first time, Level 3 participants had the exclusive opportunity to craft their own chocolate batch using exotic cacao beans from global origins and personalized recipes! With the Cocoashala Flavor Evolution/Recipe Tool, they applied their learnings to create unique chocolate bars—one they could call their own!

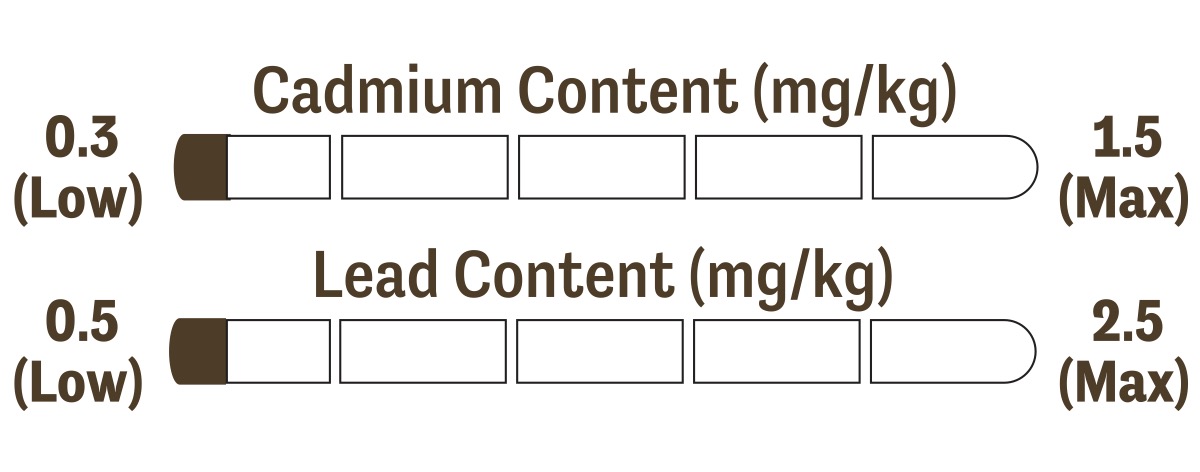

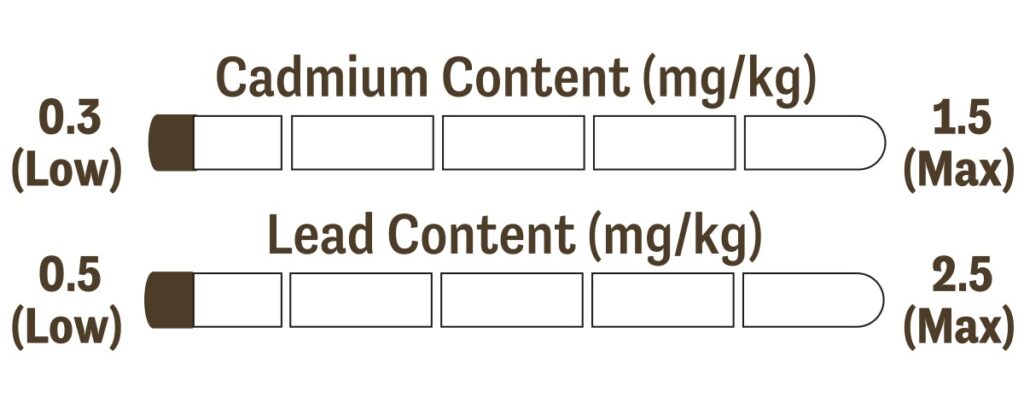

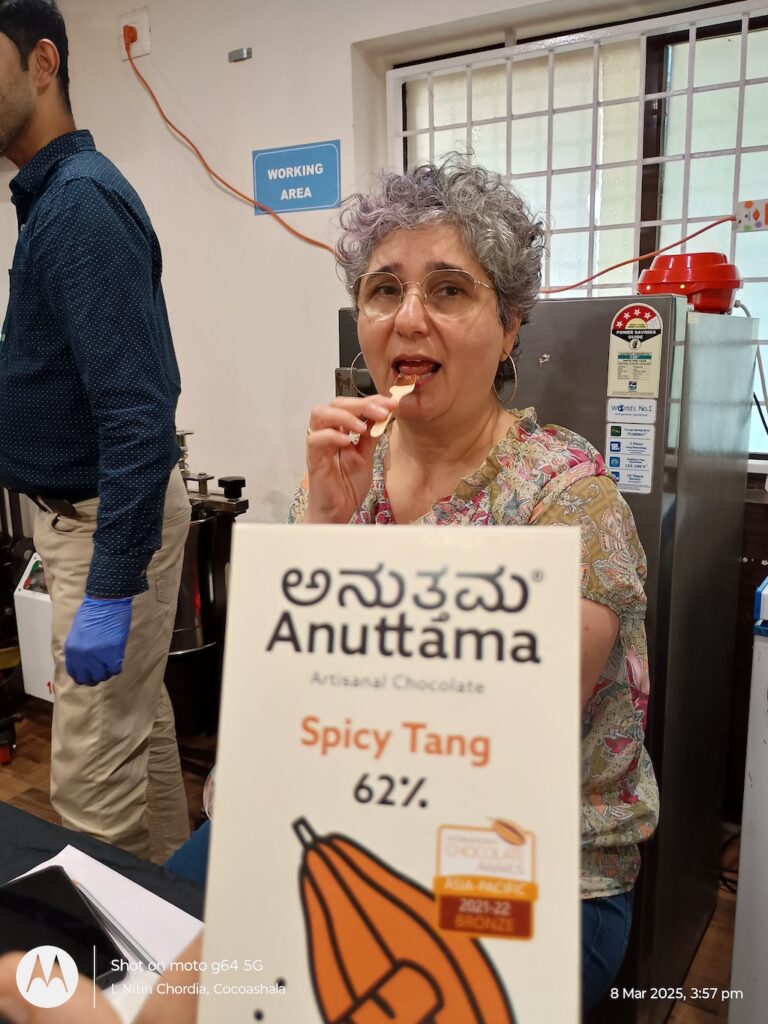

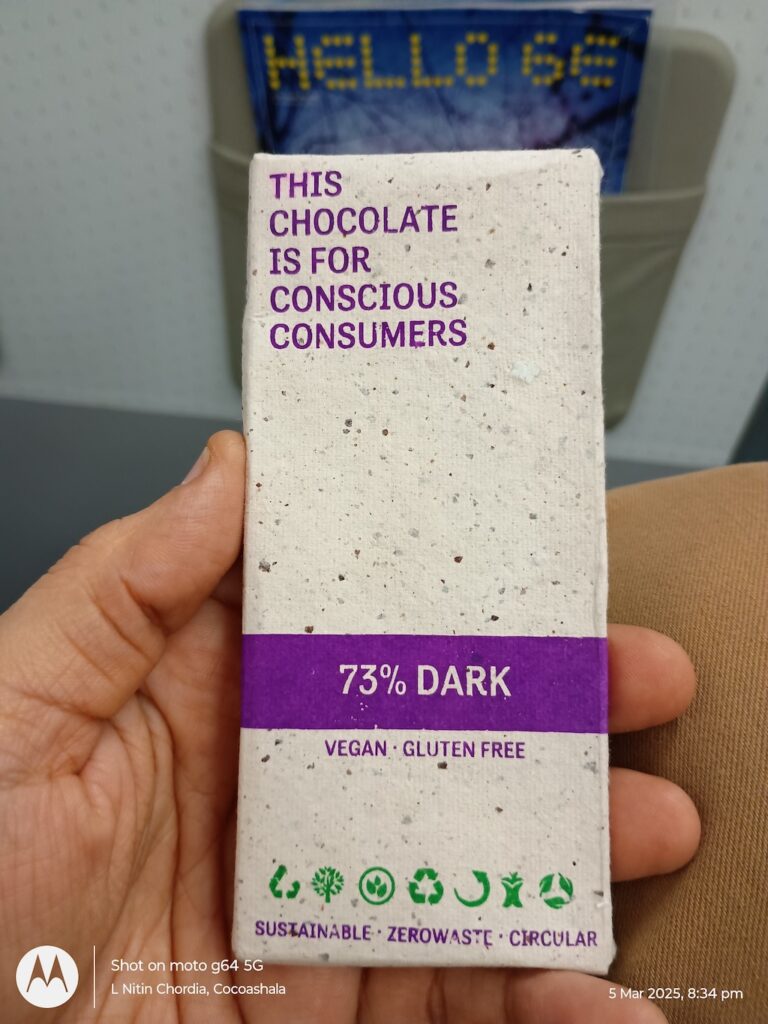

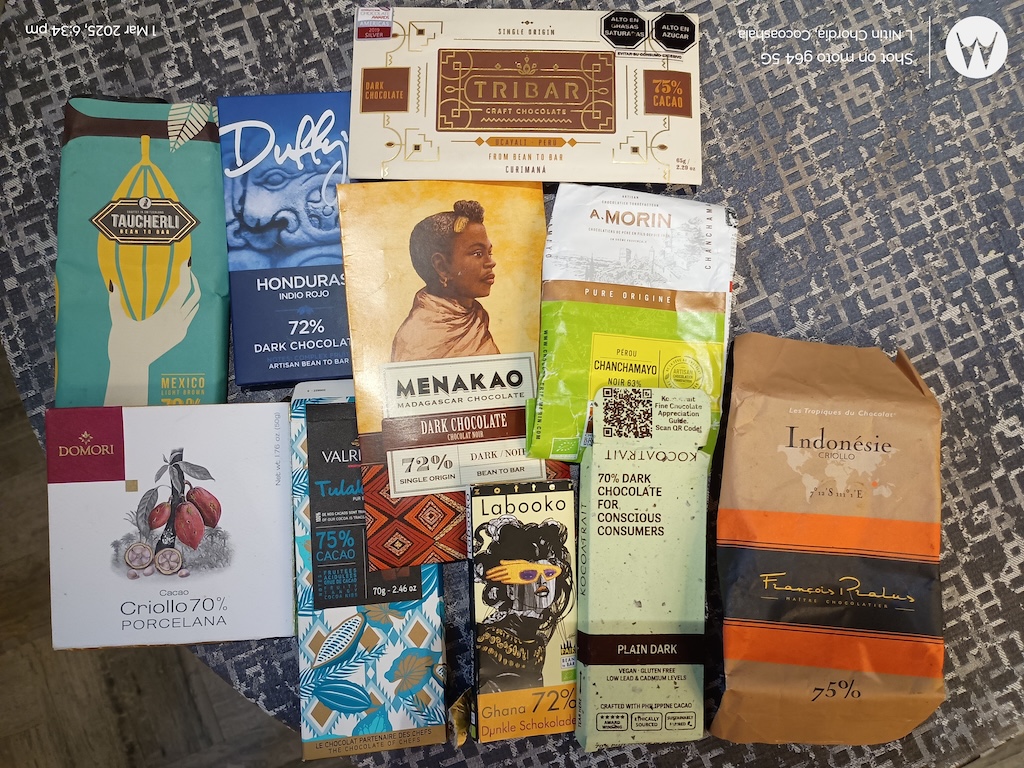

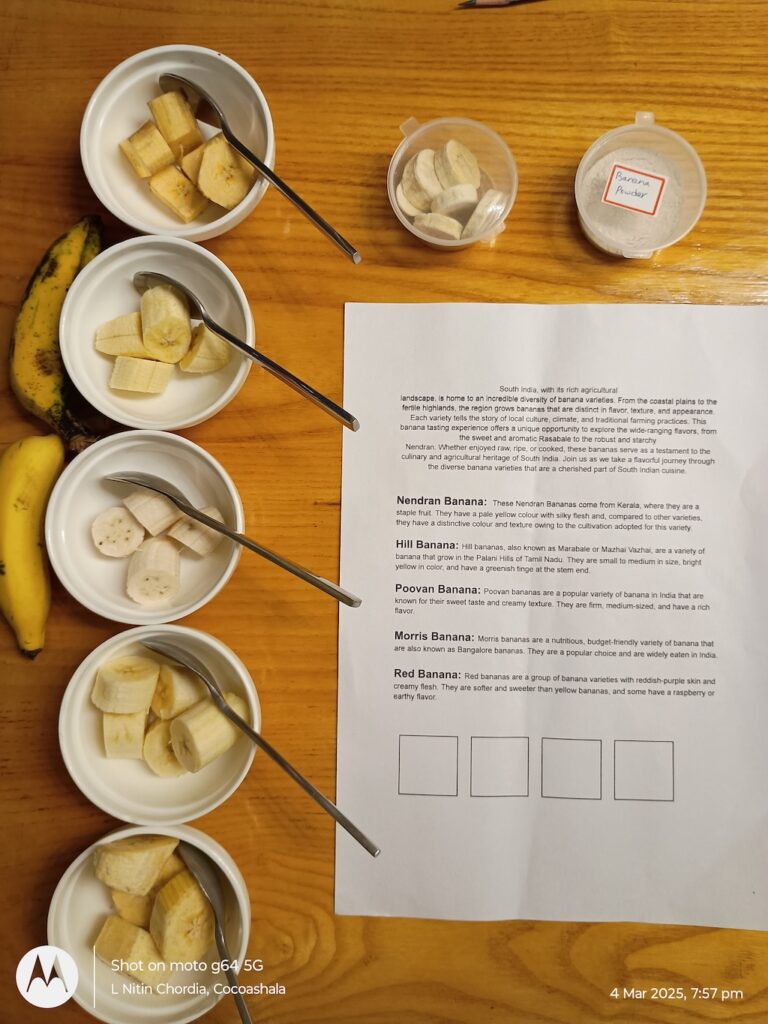

Beyond the Classroom: A Chocolate Odyssey

The experience extended far beyond theoretical learning. Attendees explored cacao fermentation units, cocoa farms, and chocolate-making facilities across three Indian states. They even participated in a blindfolded chocolate tasting at 30,000 feet altitude while on a flight! and also indulged in the rich diversity of Indian cacao origins and various local and relevant culinary delights including banana tastings, coffee tastings, milk powder tastings, sugar tastings, cocoa butter tasting and of course tasting over 50 varieties of chocolates! The program gave them first-hand exposure to the rich diversity of exotic cacao origins, preparing them to become true experts in the field.

Why This Certification is a Game-Changer

With India poised to become a global leader in bean-to-bar chocolate, obtaining a Chocolate Taster certification from Cocoashala isn’t just a personal achievement—it’s a game-changer for anyone serious about making an impact in the chocolate industry.

“Cocoashala is the world’s first and only comprehensive incubation unit for bean-to-bar chocolates. Over the last eight years, we have shaped the future of India’s craft chocolate industry, enabling many of the country’s top craft chocolate brands to succeed and training them in chocolate tasting and bean-to-bar chocolate making.” – L Nitin Chordia, India’s First Certified Chocolate Taster and Co-founder of Cocoashala.

Don’t Miss Out – Your Chance to Join the Next Batch!

If you’re feeling the FOMO, here’s some good news—the next edition of the IICCT Chocolate Tasting Certification Course is coming soon to a city near you in India! Seats are already filling up, so pre-enroll now to secure your spot.

📞 Call India’s first certified chocolate taster, L Nitin Chordia, at +91 9600064846 or visit www.cocoatrait.com to sign up!

About Cocoashala

Cocoashala is a pioneering institution and incubation unit dedicated to fostering excellence in bean-to-bar chocolate education in India. Co-founded by L Nitin Chordia and Poonam Chordia, India’s first certified chocolate tasters, Cocoashala is on a mission to transform India into a global hub for award-winning chocolate brands. Their world-class training programs are designed for professionals looking to master the craft of chocolate tasting and chocolate making.

If you’re serious about chocolate, becoming a certified chocolate taster might just be your golden ticket into the world of fine chocolate! Contact us now! +91 9600064846 or nitin@cocoatrait.com