As part of our contribution towards doubling cacao farmer income, inclusivity and atmanirbhar bharat initiatives, we offer cacao post harvest (Fermentation/Drying) and Bean to Bar chocolate consulting services as a strategic sparring partner to Indian Cacao farmers and chocolate entrepreuners. We work with businesses at all stages of development from pre-startup and start-up to multinational corporations, FMCG companies and cacao farmers looking to step up to the next phase of their cacao/chocolate journey. We help set up test cacao fermentation centers to large scale centers and bean to bar innovation labs which can produce R&D samples untill full scale production units which can process/produce 100 tonnes of cacao into chocolate.

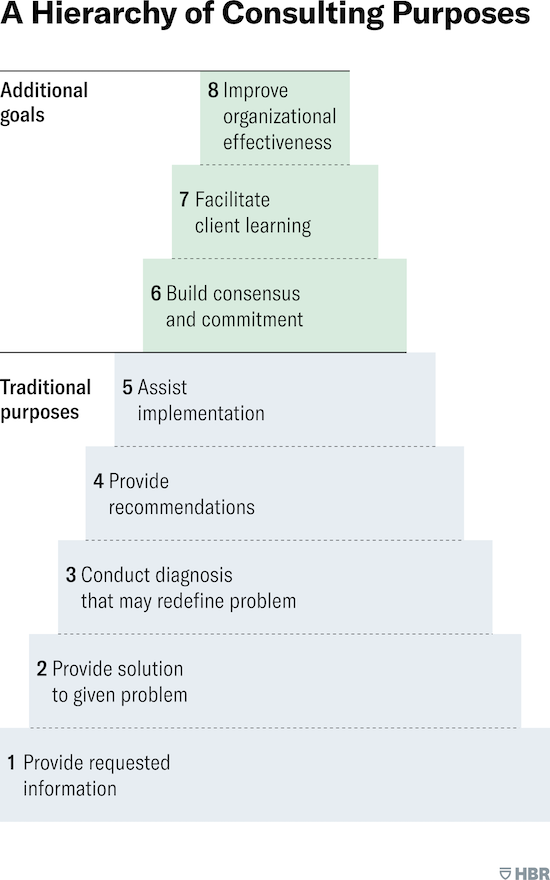

Apart from delivering the traditional purposes we, as consultants are hired for, we aim to cater to the additional goals of an organisation as a sparring partner to ensure that clients can build a business which is agile, future proof and able to cater to the ever changing market scenario/needs. Our consulting process starts with spending 3 days for the Micro Batch Bean to Bar Chocolate making certification program at Cocoashala, Chennai to ensure that clients are on the same page before the commencement of an engagement. Taking a leaf from Nitin’s 15+ years of consulting experience working with clients globally, Nitin has tailored Cocoashala’s unique and one of its kind engagement approach to be a sparring partner stemming from a clear understanding and belief that projects succeed when right expectations are clearly set before commencing an engagement and fail only when expectations are not set right.

Demand for cacao and chocolate is continuously rising but the cacao farmer continues to get neglected in this growth. Traditionally, cacao farmers have not been subject to receiving the same benefits as the other partners in the cacao/chocolate value chain. They have forever been excluded. Post harvesting is arguably one of the most important variables after genetics that determine the final flavour profile of the cacao bean and hence the final chocolate bar. Please read the current state of Indian cacao here. However, there is a clear distinction between bulk and fine flavour cacao. Let’s first start with busting the myth about cacao varieties. Please read about the different cacao varieties in India here.

Once you have read the contents of the above link, you would also notice that the cacao and chocolate industry has started to distinguish between varieties of cacao and started to group them as as Bulk or Fine flavour cacao. It will help to understand the difference between the two.

Cocoa is like grapes. You can decide to either make grape juice or fine wine!

L Nitin Chordia, Cocoashala

But before you read ahead, kindly observe that there is no such thing as quality in cacao. The term Quality is used most often by the buyer to negotiate a better price from the seller and there are some parameters which are used to determine the quality and give the power of negotiation in the hands of the buyer (large corporations in the case of cacao). A cacao farmer does not have much play or say in this situation because he cannot change the genetics of already planted cacao and hence the associated physical characteristics like bean size, bean count etc. The fact is that these parameters rarely define the flavour of cacao and are used against the farmers of bulk cacao during price negotiations. Given the growth of the bean to bar industry globally and in India, chocolate makers require flavour to be delivered rather than bean size and count. Smaller sized beans do not always mean inferior bean! It is time farmers change the benchmark and focus on improved product delivery through flavour enhancements, control over off-flavours and consistency. The cacao farmer often stands to loose with the current approach of negotiating for cacao on these parameters! Further, the cacao farmer in India does not invest on improving the flavour profile of cacao because they feel they do not find buyers who will buy their entire produce and compensate them for their efforts. It is a catch 22 situation, since cacao farmers would never be able to negotiate a better price for their produce if they do not invest into improving their consistency and flavour. This is the reason we have invested our efforts to provide cacao fermentation consulting in india to deserved cacao farmers and help them increase their incomes.

Specific genetics help us bring out interesting flavours, however, consistent and sustainable post harvesting practises are essential to ensure that those interesting flavour characteristics are carried forward to the beans for chocolate makers to take advantage of. These flavours make the job of chocolate makers, of creating delicious defect free chocolate, much easier and helps them deliver memorable and immersive chocolate experiences to the discerning consumer. This is the reason farmers charge a premium for these value added cacao and chocolate makers can charge a premium too! Most hierloom cacao varieties are fine flavour and grow in the south americas. In the case of bulk cacao, which is what makes for most of indian cacao, the hybrid varieties are engineered to either provide disease resistance and/or offer more yield with a compromise on the final flavour potential. This is a reason why bulk varieties of cacao are not sold at a premium.

However, it is not all bad news for Indian cacao farmers! With a lot of discipline and effort in the post harvesting practises, it is proven that we can elevate the flavour delivery ability of bulk varieties of cacao and make it more valuable from a flavour and consistency perspective. It does not mean it can compare or compete with fine flavour varieties, but it certainly means more remuneration for indian cacao farmers and chocolate makers. As the bean to bar market evolves, variations in post harvesting practises also give cacao farmers an opportunity to offer different products to meet different requirements of the chocolate maker. Our cacao fermentation and post harvesting consulting services in india help cacao farmers charge a premium for their produce. This increase in farmer income goes a long way in farmers investing efforts and achieving our goal of placing Indian cacao on the global map! Please read why we should choose to consume bean to bar chocolates made in India here.

Having executed several small, medium and large scale post harvest improvements projects in south india over the last 4 years, we remain committed to improving the quality of the Indian cacao bean. While discovering and working in various cacao growing regions including Karnataka, Andhra Pradesh, Kerala and Tamilnadu, it is interesting to learn about traditional fermentation practises (and beliefs) of Indian cacao farmers. We believe that Indian cacao has potential to find a place in the global fine flavour map. Further, we provide end to end bean to bar chocolate manufacturing, planning & set up services. We have set up several small and medium size award winning bean to bar projects in India. To understand the definition of bean to bar chocolate in india, click: https://cocoatrait.com/bean-to-bar/bean-bar-chocolate-india-definition/ and to explore more about the bean to bar making process watch video below: https://www.youtube.com/watch?v=0srVqupalpQ

We aspire to take Indian cacao international and call for support from the farmer community. L Nitin Chordia, India’s 1st certified chocolate taster believes that this is an inclusive offering and will work in the benefit of the farmer and the overall growing bean to bar chocolate industry. “This will further help us decrease our reliance on imports of cacao/chocolate” says L Nitin Chordia. “While the government is trying hard to increase the area under cultivation of cacao in India, this added effort and investment from the farmer would help him increase farmer income and make good quality beans available to the Indian bean to bar chocolate makers. We are happy to share our expertise and experience for this cause. This will ensure many more chocolatiers will have access to fine flavour beans and I see this as a win-win situation for the Indian cacao and chocolate industry. This will set the foundation to support the unprecedented growth this industry is witnessing” says L Nitin Chordia. Kocoatrait further provides buy back options to farmers and clearly documents the ROI to enable farmers make an educated and informed decision.

Vikas Temani—Business Head, Paul & Mike Craft Chocolates.

Akhil Grandhi, Bon Fiction Bean to Bar Chocolates.

Harish Manoj Kumar and Karthik Palanisamy of Soklet took samples to Chennai-based L Nitin Chordia, India’s first certified chocolate taster, and asked him to give them a try. “If he wasn’t going to like them, both the idea and the chocolate were going to be binned,” said Palanisamy. But Chordia liked what they’d done and that led to birth of bean-to-bar brand Soklet.

Karthikeyan Palanisamy, Co-Founder, Soklet Tree to Bar Chocolate, India.

Progressing from cocoa to chocolate, we offer sparring partner, end to end consulting, implementation and incubation services to help set up bean to bar chocolate units. An introduction to the role of a sparring partner and its difference when compared to a traditional consultant would be worth mentioning at this stage.

A sparring partner is someone who challenges you to think critically and offers a fresh perspective on your ideas and decisions. In the context of business, a sparring partner can play a crucial role in helping you refine your strategies, identify blind spots, and prepare for potential challenges.

Here are some of the key benefits of having a sparring partner in business:

- Honest feedback: A sparring partner can provide honest and constructive feedback on your ideas and decisions. This can help you avoid making costly mistakes and improve the quality of your decisions.

- Different perspective: A sparring partner can offer a different perspective on your business challenges and opportunities. This can help you see things from a new angle and come up with more innovative solutions.

- Challenge assumptions: A sparring partner can challenge your assumptions and force you to consider different scenarios and perspectives. This can help you avoid complacency and stay ahead of the curve.

- Accountability: A sparring partner can hold you accountable for your actions and decisions. This can help you stay focused and motivated, and ensure that you are taking the necessary steps to achieve your goals.

Overall, a sparring partner can be a valuable asset in business, providing you with the support and guidance you need to succeed. Our services are aimed at achieving product, process and business excellence and usually include (but are not limited to):

- On boarding using our 3 day bean to bar training program – This is our unique consulting approach and we work with the belief that most project failures are attributed to not setting the right expectations. This interaction helps us set the right expectation with the farmer/entrepreuners.

- Drawing out a business plan/positioning based on market trends, gaps, opportunity and business fit.

- Choosing the right raw materials including cacao bean, sweetness, inclusions, infusions, flavour additives, emulsifiers (based on origin, flavour, value, required end product specifications etc)

- Raw Material supplies (International & Indian cacao bean etc)

- Equipment / Machinery selection based on flavour, format, quality and quantity requirement

- Equipment / Machinery Import & Supplies based on criticality and contribution of each step towards the process.

- Providing technical inputs to project/technical teams for machine installations

- Location/Site selection based on storage, production and consumer experience goals

- Equipment / Machinery installation assistance/inputs

- Product Variant/Range/shape/Size selection

- Recipe Development/Formulation based on chocolate application

- Standardising processes and production schedules

- Quality Controls and measures

- 1st level staff/operator training

- Brand Name Selection, Logo, Trademark, Packaging & Brand consulting

- Pricing, Distribution and Marketing Strategy

- Consumer Engagement and Education activities

We now provide incubation services to cacao farmers and chocolate brands while assisting in setting up their processing unit. This helps them reduce time taken to market and also gives them time to do product/consumer testing before hand.

Contact us for a detailed discussion on how to improve the post harvest practises of Indian cacao and start up a new cacao / chocolate business venture. nitin@cocoatrait.com and/or +919600064846

Contact us for a detailed discussion on how to improve the post harvest practises of Indian cacao. nitin@cocoatrait.com and/or +919600064846