India’s 1st Sustainable Zero Waste Chocolate

Chocolate as a food product is among the highest contributor towards climate change and has a large carbon footprint. Take for instance, an average 40-gram bar of industrially produced milk chocolate will carry a carbon footprint of approximately 200 grams or five kilograms of carbon per kilogram of chocolate. Some estimates point it as 47 Kgs of Carbon Dioxide Equivalent (Co2e) emissions per Kg of chocolate primarily due to land use change. To put things in perspective, over one year, a mature tree will take up about 22 kilograms of carbon dioxide from the atmosphere, and in exchange release oxygen. Based on our internal calculations, each 40 gram bar of Kocoatrait chocolate, on an average, is responsible for emitting 1.34 kgs of Co2 into the atmosphere. Bean to Bar (craft) chocolate makers in india and overseas tend to have a larger carbon foot print per bar simply due to usage of less energy efficient machinery and low economies of scale. We do not want you to stop enjoying chocolate. With the information on this page, we wish to sensitise you to the fact that needless consumption and bingeing of chocolate should be avoided if you care for the planet and support the cause of India’s 1st Sustainable Zero Waste Chocolate.

Disclaimer: We are trying to address 6 specific issues with our Cacao & Chocolate initiative @ Cocoashala & Kocoatrait. A) Cacao needs a lot of water to grow. For Ex: The amount of water needed to grow 1 kg of cacao can help grow 34 kgs of apple and 1000 liters of water are used to produce a 100gm chocolate bar! B) Cacao farming leads to soil contamination and herbicide resistance C) A lot of the world’s cacao is grown on deforested lands. D) cacao farming involves child labour E) Lot of unsustainable palm oil is used in chocolate and F) single use plastic chocolate wrappers are a substantial cause of landfills. We recognise these stated facts and hence focus our best efforts on addressing each of these issues. We have addressed the latter 5 issues via our chocolate brand Kocoatrait (read on for more) and submit that we have not been able to address the high water usage issue in cacao farming yet. We shall perhaps not be able to address the water issue for some time to come. However, we can promise that we will be among the 1st to invest our efforts into ensuring lesser usage of water during cacao farming when it is possible. To ensure we go to sleep well everyday, (thats why we are in the chocolate business!) we use no water as an ingredient while making chocolate and the water we continuously collect from our dehumidifiers (we make chocolate in the humidity of the tropics in madras!), are used for cleaning the floors and a bit of our washing needs. We aspire to positively contribute to the planet by being carbon positive and take Extended Producer Responsibility seriously. We have made significant strides by introducing our wrapper return program recently.

We are guided by the 17 UN Sustainable Development Goals (SDGs), which are an urgent call for action by all countries – developed and developing – in a global partnership. Kocoatrait addresses 12 out of the 17 SDG’s listed below:

GOAL 3: Good Health and Well-being

GOAL 4: Quality Education

GOAL 5: Gender Equality

GOAL 8: Decent Work and Economic Growth

GOAL 9: Industry, Innovation and Infrastructure

GOAL 10: Reduced Inequality

GOAL 11: Sustainable Cities and Communities

GOAL 12: Responsible Consumption and Production

GOAL 13: Climate Action

GOAL 14: Life Below Water

GOAL 15: Life on Land

GOAL 17: Partnerships to achieve the Goal

Thank you for reading this and we hope that you will read on further to understand our sustainability initiatives and support our cause wholeheartedly.

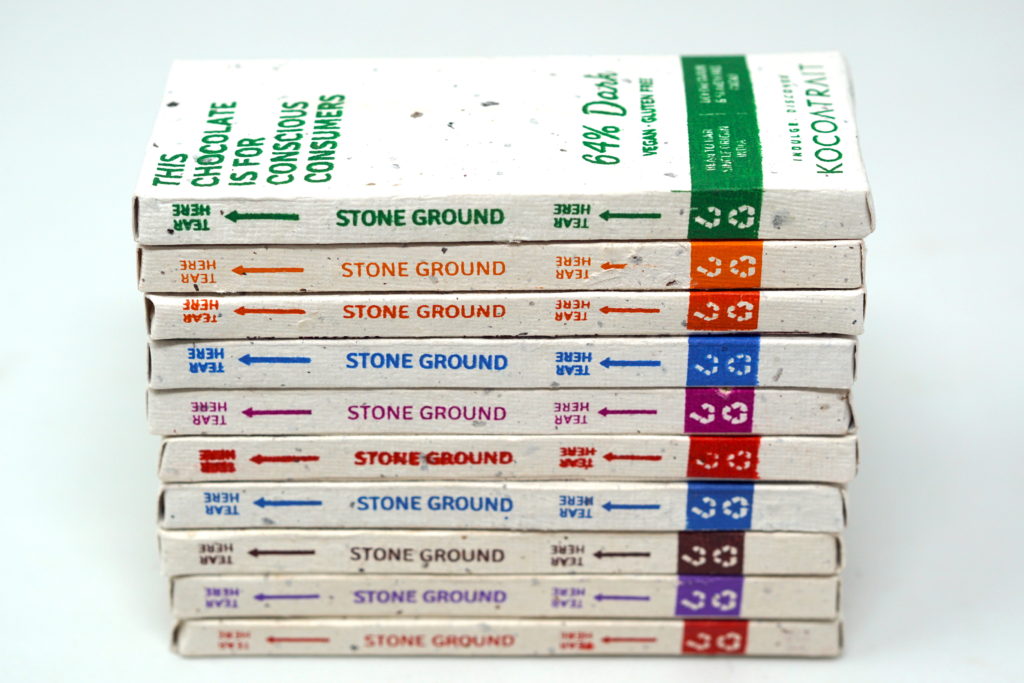

Kocoatrait is the world & India’s 1st Sustainable Luxury and Zero Waste Chocolate. Kocoatrait is a Plastic Positive (or negative which ever way you look at it), Single Origin, Organic and Planet Friendly Bean to Bar Chocolate contributing to the circular economy. Kocoatrait was conceived with an aim to enable aspiring Indian citizens to adopt a zero waste lifestyle and follow minimalistic living. Our 5 P’s of priority are People, Planet, Plants, Performance & Profits (in that order). We focus on adopting and implementing sustainable practises starting from the cocoa farm through to production, packaging and distribution of cocoa and our chocolates. Our chocolate offerings overall are Plastic/Paper/Wood Pulp/Tree free. We sleep well at night being assured that we have cut no tree in our pursuit of offering Fine flavoured Indian single origin bean to bar chocolates to planet concious consumers like you. Kocoatrait, India’s 1st Zero Waste Chocolate has helped save 300+kgs of single use plastic from ending up in landfills. Sustainability to us extends to more than just being plastic free. Sustainability literally implies continuity and we have added social inclusivity to our definition of sustainability. We believe that every step of making chocolate helps us discover traits of cocoa. We also believe that less is more and we try hard to ensure you have lesser of our chocolates and not more of it! To achieve this we encourage you to refer our chocolate tasting guide where we discuss the steps for fine chocolate appreciation and how less is actually more! We have a long story to tell but we shall try to keep it short and relevant starting from our farm ingredient, cocoa and travelling outwards towards the chocolate packaging.

At the Source – Cocoa Farm

At the farm level, our cocoa is fermented in a 5-7 day slow process in wooden boxes and only sun dried which helps us retain fine flavours and helps us enhance the flavour of our final chocolate. Sun drying helps us promote the usage of naturally available solar resources and helps us avoid smoke pollution and tree felling which is the usual way to artificially fast dry cocoa in commercial scale. We pay more than designated fair trade prices to our farmers who do not employ any child labour on their farms. Illegal deforestation for the purpose of planting cacao is a global issue but the good news is that, in India, it is not commonplace at all. Cacao is an additional plant and source of income for Indian farmers and is planted in land that is already used for crop cultivation and has shade trees like coconut, arecanut, rubber, oil palm or coffee thus keeping the bio diversity intact to a great extent and assuring diversity in farmer incomes too! Further, we try to ensure that all cacao sourced are from land that have not been illegally deforested for the purpose of growing cacao. Cacao farming leads to soil contamination and herbicide resistance. Hence we ensure that we purchase only organically grown beans and ensure that we do not cause further damage to the soil. Our cacao travels to us from within 550 kms from our production unit in chennai and we use road transport to minimise the carbon footprint. We use only single origin Indian cacao to make our chocolates. The cocoa farm is our inspiration to be India’s 1st Zero Waste Chocolate.

Our Ingredients

We use ingredients that are locally manufactured and sourced from within india. This helps us reduce our carbon footprint, promote atmanirbharta and remain sustainable. Remember we said, continuity is a part of sustainability for us! We use only non refined sweeteners like desi khaand (khandasari) sugar, palm sugar, jaggery or dates in our chocolate. We use only natural flavours in our chocolates. We do not use any synthetic or artificial flavours or essential oils since they follow a chemical or alcohol based extraction process which is not sustainable. It is simply an additional process which we always avoid. For instance, our Red Rose chocolate bar would have real rose petals ground with our cocoa beans to make chocolate! Similarly, our Espresso chocolate would use real coffee beans and our Masala Chai chocolate would use real whole spices like cardamom, ginger and black pepper. Is there a right way to taste chocolate? Yes! There is! Click to know more! https://cocoatrait.com/chocolates/how-to-taste-chocolate/ Our chocolates are made using cold pressed cocoa butter at our facility. We cold press our own cocoa butter and do not use any vegetable oils as they are super processed! We roast most of our cocoa at 110-118 degrees celcius depending on our chocolate variant as it causes negligible changes in total phenolics content and antioxidant activity of cocoa beans. Recently dark chocolate has been more spoken about because of its perceived health benefits. Is there truth to it? Click to find out: https://cocoatrait.com/chocolates/best-dark-chocolate-brand-in-india/https://cocoatrait.com/chocolates/best-dark-chocolate-brand-in-india/

Our Production Process

Taking about our production process. We do not use LPG for roasting since gas is a non renewable resource. We use energy efficient electricity based air roasters to roast our cocoa. We currently do not use solar or wind energy but the use of air roasting, sets the foundation for our processing to use any greener form of electricity in the future. We have developed and innovated our cracking and winnowing equipments in-house and we can proudly say that our cocoa cracking/winnowing equipment is perhaps the most energy efficient equipment one can find! We use only traditional south indian stone grinders to grind our cocoa. This helps us worry less about metal contamination in our chocolate. We must admit through that they might not be the most energy efficient but we use them but it helps us retain flavours as it assists in low heat processing of our chocolate. We do not use any imported equipment for our chocolate processing except our chocolate melter, a wine chiller and an air dehumidifier since we need to be accurate while hand tempering our chocolate. We manually hand temper each batch of chocolate. While we may not be perfect, we pride ourselves in our imperfections followed by our improvements constantly. We are a “all women production workforce”. We employ women of our local community only. Poonam Chordia, Founder of Kocoatrait heads the production.

Our Primary Packaging and Printing

Coming to the perhaps the most talked about aspect of chocolate industry. The chocolate wrapper. In 2019, a deep sea diver found candy wrappers at the bottom of the ocean! We decided that this should be the greatest problem area to which we must find a solution. Our chocolate wrapper is Upcycled using reclaimed cotton from garment factories and reclaimed cocoa shells (which is a byproduct of our roasting process) making it Biodegradable, Compostable and Recyclable. We have selected a size and shape of the chocolate bar mould to ensure that we have minimal wastage while die cutting the upcylced material to form our outer chocolate box. Currently, 16% of the material (corners mostly) are wasted when we die cut. The shape and size of our chocolate bar was also selected to ensure that we reduce our volumetric weight which helps us reduce the overall freight space and helps us save carbon footprint. We pride ourselves on using the same wrapper size as the chocolate bar. We do not enclose a smaller bar of chocolate in a large wrapper to make the chocolate look bigger than it actually is. This is a common practise in the industry. With Kocoatrait, what you see is that you get! We do not make bite sized individually wrapped chocolates because they have the worst impact on the environment. We make the chocolate zero waste by printing various consumer engagement ideas (like greeting cards, Bookmarks, mandala art templates and health trackers) on the inside of our wrappers. We first wrap our chocolate in a virgin and recyclable pharmaceutical grade aluminium foil and encourage reuse. It helps us save the chocolate from the temperature and humidity fluctuations better than most other materials laced with plastic. It does not have any lamination and hence is 100% recyclable. In fact, aluminium is the most recycled material in the world. We use only water based inks making it compostable, biodegradable and recyclable. Most of our printing is done at V-Excel Educational Trust, Chennai which trains differently abled Indian citizens. While we do not want to over burden them with our work but they are our 1st go to printing partners. Only in the case of lack of capacity we get our prints outside. We are proud of our wholehearted support to them.

Our Secondary Packaging

Finally, when we talk about our outward e-commerce shipments, we do not use any single use plastic in our SHIPPING boxes used for secondary packaging. We have now made all our small sized e-commerce boxes as reusable and made with recycled and forest friendly paper! Our small boxes can be re-used for 5 different applications including Gift box, Desk Organiser & Mobile holder, Tablet Holder, Bird house and Plastic bag dispenser. Check out the video here. We use paper bubble wraps and paper tapes for our boxes. We include a reusable non toxic gel ice pack in our intercity ecommerce shipments for insulation. We do NOT use thermocole boxes or plastic tapes. We have optimised the sizes of our boxes to reduce carbon footprint. We have started to use (when possible) Earth Friendly and Tree-Free Paper Manufactured from Agro by products of Sugarcane Bagasse, Wheat Straw & Wild Grass to print the Bluedart Airway bills and all the communication/inserts that go into the box. No tree has been cut to make this paper! This is a innovation called Print Pro. Shop for Kocoatrait chocolates at: https://cocoatrait.com/product-category/shop/kocoatrait-chocolates/ We are on Instagram at: https://www.instagram.com/Kocoatrait/

Things we acknowledge we can improve upon:

- Tamper proofing our chocolates better (without having to tear the wrappers)

- Reverse logistics program to give an option to the concious consumer to return back the aluminium boxes, wrappers or the cardboard box (WE HAVE UPDATED THIS AS OF DECEMBER 2021 AND FOLLOW A EXTENDED PRODUCER RESPONSIBILITY PROGRAM WHEREIN WE REUSE AND UPCYCLE ANY WRAPPERS SENT BACK TO US)

- We are currently having to use thin plastic cellotapes to stick the Bluedart Airway bills on top of the cartons. We shall stop this soon! For the box however, we use only paper tapes to tape the box.

- A few herbs we use in our Sukku chocolates are not organically grown. We do not mention them as organic either in the ingredient list. Going by the % we use them in, it is insignificant but we shall be striving to source them organic as well.

- Not all our products are vegan. We have 3 products which contain A2 milk. A2 milk is considered more flavourful and we source them from self certified cruelty free farms. We are however, aiming to discontinue these variants sooner than later.

- We do not contribute to the education or other social welfare of the cocoa farmers as of now. We only buy at more than fairtrade prices. We aim to be involved in their overall well being going forward.

- We do not contribute to increasing the biodiversity of the cocoa farm currently. We aim to start to play a role soon

- The gel ice packs we use are reusable and non toxic but are packed in plastic. They are not single use and can be reused multiple times at home (for treating body pains as cold packs or transporting cold food). We are actively looking at alternates to reducing the use of this plastic by better insulation and/or a smaller size of the ice pack. Unfortunately, in our tropical climate, we are restricted to the usage of these to protect our chocolate from melting.

- We aim to reduce the wastage while die cutting our upcycled material to less than 16% as we move forward.

- We would like to be a business operation where we have not felled a single tree to operate our business. We want to acheive this by using recycled and upcycled paper for office use and for our e-commerce shipping boxes. (WE NOW USE PAPER MADE OUT OF AGRO WASTE TO PRINT OUR DOCUMENTS AND SHIPPING LABELS AND OUR E-COMMERCE SHIPPING BOXES ARE NOW REUSABLE AND MADE FROM RECYCLED PAPER.)

About Founders of Kocoatrait: L Nitin Chordia is India’s 1st certified cacao & chocolate taster. Poonam chordia is India’s 1st certified woman chocolate taster. Cocoatrait is an initiative to bring the best fine chocolates to consumers in India for their appreciation. Cocoatrait represents Indian chocolates across the globe and is involved in promotion of fine chocolates across India and the globe. We’re based in Chennai, India. We also operate a bean to bar chocolate making institute called Cocoashala and offer a 3 day bean to bar chocolate making program. We have partnered with IICCT, UK to administer the Chocoate Tasting Certification courses in India. We have incubated multiple brands at Cocoashala and have also invested into building Kocoatrait, India’s 1st Zero Waste Chocolate. Kocoatrait is the Worlds 1st Sustainable Luxury, Zero Waste, Planet Friendly (Plastic & Paper free) Vegan Ecofriendly Sustainable Bean to Bar Chocolate brand.

Nitin is a retail business consultant by profession with more than 15 years of experience working for large retail consulting companies in India, UK and USA. Nitin is currently India’s 1st and only certified chocolate taster and an active member of judges at the International Chocolate Awards based in London. Nitin travels the world in search of fine Cocoa/Chocolates and operates Cocoatrait. Nitin’s main objective with his efforts is to promote the creations of chocolate makers, to connect them with chocolate lovers. Please connect with us at: nitin@cocoatrait.com or +919600064846. We are on Instagram at: https://www.instagram.com/Kocoatrait/

Please let me know if you have bean t bar training for cacao & chocolates in India, I’m interested.

Hi Candice, We have an online and a face to face bean to bar chocolate making program. Please click on: https://cocoatrait.com/product-category/shop/events/ and/or call/whats app +919600064846.

Hi There,

I have been always wanting to try Ceremonial grade Cacao but never do find the same in India. Kinda stumbled upon this page and was curious to know about Cacao.

Wanted to confirm if you guys do arrange a cacao circle or do have ceremonial grade cacao in stock?

WIth Love & light,

Vaibhavi