Disclaimer: This is not meant to be a religious post and we are not Jain monks who, ofcourse, have far greater understanding of these issues discussed. We both have been born in Jain families and aim to practise the rules set out by Jainism as accurately as possible. Also, we are not an externally funded business/brand. Last but not the least, I hope this does not turn into a religious post. I am an all-welcoming democratic citizen of India and an aspiring Jain. Though I have the privilege of having been born into a Jain family, I do not yet follow strictly all the guidelines/rules and hence am choosing to use the word “aspiring jain”. But Jainism is embraced by families like ours and we choose to aim and adhere to its guidelines because it does not enforce the rules onto its followers.

We, Poonam Chordia & L Nitin Chordia are India’s 1st certified chocolate tasters and Co-founders of Kocoatrait chocolates. We feel that we have come a long way in our chocolate journey and should take a moment to summarise the inspiration behind what has helped us tide through Covid with very high empathy, compassion, self-belief and optimism to make a difference to the planet we live in and the people we live around.

As we welcome the year 2023 with measured optimism and with a belief that this year is going to be pivotal for the cacao and bean to bar chocolate industry in India, let us start with seeking forgiveness with folded hands for the unintentional wrongs that we might have done and hurt anyone while making progress in the past year. Micchami Dukkadam. Ofcourse, you might have guessed by now that this is related to us being Jains!

We discuss how the values, principles and practises of Jainism that we have been surrounded by during our formative years have guided us into building our business verticals namely, Cocoashala as Asia’s 1st and only bean to bar incubation centre and training institute, Kocoatrait as India’s 1st and only Zero Waste, planet friendly, Inclusive and sustainable chocolate brand and Cocoatrait as India’s 1st and only cocoa post-harvest solution and service provider and have helped us in the choices we have made in our chocolate business.

For starters, Jains have for thousands of years believed in respect for all living beings including plants and animals. The central philosophy of Jainism – one of the world’s oldest religions – is Ahimsa and is based on non-violence in thought, word and deed/actions. Jainism is a life style of values, which is alternative to the ideology of consumer society or consumerism. It is characterised by the virtues of non-violence, non-possession, non-absolutism and equality of each soul, which balances the internal happiness along with socio-eco harmony. Its philosophy educates, trains and motivates a human being to limit the strive for power and desires within the circumscribe of availability. Jains are inspired to work with what is available within nature and limits of money and to practise a compassionate form of capitalism. Sustainable Development (SD) for Jains is based on the following major factors:

Economic Development

A lot of today’s world problems arises due to the need or greed to amass more wealth than others resulting in increasing consumerism. Jain philosophy considers all earth-bodied, water-bodied, air-bodied, fire-bodied, plant-bodied and the moveable creatures as a living being and any harm to these is considered as violence. Apart from Non-Violence, Jainism also preaches and requests followers to practise non-possession or what the modern world today refers to and is knows as Minimalism. Excess utilization of water, food, clothes and other resources is considered as causing or indulging in violence. It can also be termed as principal of economic humanity as it teaches disassociation of attachment with the available resources and to act like a custodian for the same. This principal includes avoiding hoarding of things more than what is required.

How Cocoatrait, Kocoatrait & Cocoashala has benefitted from the above principles: At Kocoatrait we have based our offering on less is more! We have designed our chocolate products and experiences to ensure we help consumers keep a tap on over consumption. We do not cut a single tree to operate our business. Cacao fruits are cut with specific care and we train farmers to ensure that the location from where the fruits are picked are not damaged and the tree produces fruit again next season at that location. Further, minimalism is stitched into the Jain philosophy and we are big on minimalism. Starting from our minimal graphic design, the optimised size of our bars and the minimal amount of packaging material we use on our bars, our focus on minimalism all the way! We design our chocolates by making most use of resources to ensure that the least quantity of consumption results in a more than usual amount of satisfaction (of flavour) thus encouraging lesser consumption and discouraging consumerism. We include a chocolate tasting guide to help reduce consumption.

Ecological Balance

Jain philosophy, based on non-violence, is a vigilant security guard of ecological balance. Don’t kill any living beings, don’t try to rule them is the core preaching and practice of Lord Mahavira. Jains have been under pledge not to causes harm to any birds, animals, flora and fauna and allows them to grow in a fearless environment. Jains are prohibited to cut green trees and kill even tiny living beings. A Jain should be a strict vegetarian, consume food before sunset and fast regularly. This life style leads to automatic conservation of nature, limits consumption and increases understanding of and accepts the respectful survival of every living creature. Jain monk’s travel barefoot throughout their life thus also reducing vehicular pollution and reducing chances of killing insects by stamping them.

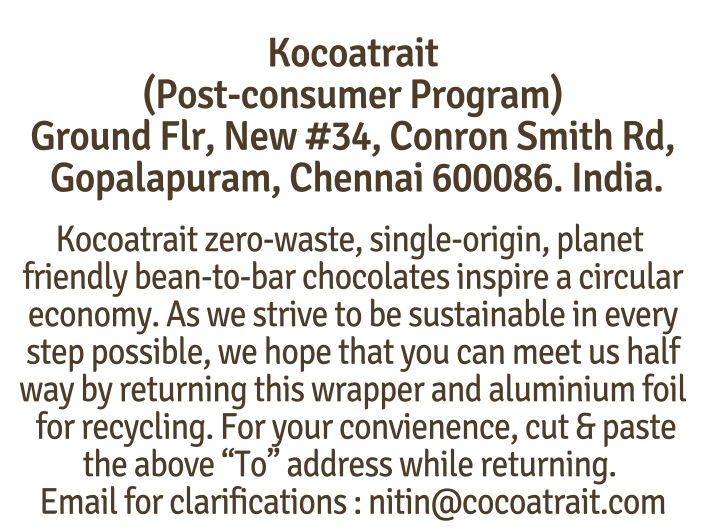

How Cocoatrait, Kocoatrait & Cocoashala has benefitted from the above principles: The beans are fermented and sun dried at the farm level to ensure that the transportation and pollution is limited. The fruit leftovers go back to the soil at the farm. Our office operation uses paper made from agro waste to ensure no tree is cut to make paper. We do not use fire to roast our beans. We procure our main raw material (cocoa beans) from within 550 kms of our unit and use innovative low energy equipment to process our chocolate. Our chocolate wrapping material is up-cylced from leftover cotton from garment factories and the cocoa husks which are left over while air roasting at our manufacturing unit. We operate in the circular economy and promote the reuse of the outer shipping box by giving the consumer various ways to repurpose them. We operate an EPR program wherein consumers can return the wrappers to us for recycling. We use water based ink to print on our wrappers and prioritise manual screen printing to reduce energy consumption.

Equality feeling

Jainism is a religion of socio-religious equality where all souls are considered and to be treated equal and does not differentiate between people of different religious faiths. Soul of ant is equally powerful as of elephant. Jainism gives equal right to women for religious practices. Jainism believes that one, who cultivates an attitude of equality towards all living beings, can attain equanimity. For many Jains, as well as those from other dharmic religions such as Sikhs and Hindus, philanthropy is “a duty not a choice” and it is a priority not an afterthought or a forced action. Philanthropy is practised as one of the ways and with an aim to elevate everyone around you to become equals.

How Cocoatrait, Kocoatrait & Cocoashala has benefitted from the above principles: We operate our business with an inclusive first mindset. We employ non jains from the local community in our business. Most of our employees are women and we are highly flexible towards their personal needs. We pay keen attention on inclusivity, thus, philanthropy, for us, is not an afterthought. The 1st choice printers for our wrappers are V-excel educational trust who train differently abled citizens on screen printing. This is to ensure that we have contributed as we start and every day and not accumulate (hoard) wealth before distributing it. We aim of giving equal opportunities to all. Our palm leaf boxes are made by financially disadvantaged rural women in tamilnadu. We engage differently abled artists, encourage them to be creative and create an art piece for us and we then print their work inside the wrapper by giving due credits. We always look for a chance to be inclusive and demonstrate equality while operating our business.

Emotional Maturity

Emotional Maturity implies controlling emotions willingly, Flexibility in attitude and to understand the sense of responsibility. Uncontrolled emotions are often responsible for conflicts at personal & social level. Jain philosophy is based on the nature of reality hence accepted the existence of opposites. Its core code of conduct includes non-absolutism, which nurtures the flexible approach to accept the different thoughts with compassion.

How Cocoatrait, Kocoatrait & Cocoashala has benefitted from the above principles:

At the farm level, our post-harvest practises/protocols have always approached treating the cacao plants and soil with care, emotionally, with great compassion, calmness and flexibility as if they were another human being and accepting that there will be batches of cacao fermentation and or chocolate making that might go wrong. Across the value chain, starting from working with farms that organically grow cacao, ensuring best practises so that all the flowers convert to fruit, keeping a check on temperatures during fermentation at every stage, to reducing wastage at every step of the post harvesting process, ensuring there is minimal fruit wastage by defining the harvest protocols, optimising batch sizes, using natural methods (sun light) to achieve correct beans drying and using shade optimally, low roasting our cacao beans, using gentle cracking and air flow to winnow the husks of our beans, keeping refining/grinding temperatures under check, our progress has been purely and surely because we treat cacao beans delicately and respectfully as a living being across the process. We accept each bean is different and adjust/adapt our process accordingly. We have gone to an extent to be vaastu compliant in the positioning of our equipment’s and processes to ensure that no negative energies are captured in our cacao beans or chocolates. Last but not the least, we pay the cacao farmers a higher price than asked to ensure that we demonstrate our compassion towards them. This, to us, has been our differentiator from the very beginning.

Educational Elevation

Education is the most important tool to establish and maintain the sustainability of humanity. In Jainism, it is said that no conduct is possible without knowledge. Further, defining knowledge, Lord Mahavira said that “with the help of which we can know the truth, control the restless mind, and purify the soul is called knowledge.” Attaining salvation is the ultimate aim of Jainism. The criteria for salvation is to have Keval Gyan i.e. attainment of complete knowledge. Knowledge through research is an integral part of Jain philosophy and continuous application of the same is the primary task. Jainism lays less emphasis on the formal knowledge but more to the practical application, which trains the person to behave in harmony with nature and other living creatures.

How Cocoatrait, Kocoatrait & Cocoashala has benefitted from the above principles:

As we operate Cocoashala, an institute aimed at spreading knowledge about bean to bar chocolate making and tasting, we have always believed that equality in society can be achieved via knowledge sharing, education and research. The aim of our 360 degree education approach with the certification courses we offer in chocolate making and chocolate tasting is to do our best to elevate all members of the industry with in-depth knowledge. We have incubated and helped establish several chocolate brands at Cocoashala without fearing them as competition and with a clear and pure approach of ensuring their well-being and progress via continuous knowledge sharing, education and training. We started with no formal education in chocolate making and we worked backwards to increase our knowledge with in-depth research. We researched and understood the final chocolate product in-depth and then backward integrated to equipment curation/contract manufacturing, and then to the farm level where we now undertake post-harvest projects. The guiding principles have been research. We have never assumed that we know everything there is to know and we have improved our understanding via practical application of our knowledge. Having no formal education has never been disability for us and research has guided us all along. Our association with IICCT, UK is also our effort to bring the best of education to the community.

I hope that you like reading this piece and I would welcome and appreciate your honest feedback. Kindly contact or whats me at +919600064846 or nitin@cocoatrait.com